Despite having a smaller population and workforce than the United States, Australia has emerged as a pioneer in construction safety. With the help of government regulation and enforcement, contractors in Australia are now required to follow stringent rules to maintain compliance with safety regulations.

However, the risk of injuries and accidents is ever present especially when heavy duty electrical equipment is being used daily.

Common Electrical Risks

When working with electrical systems and equipment, It is important to remember that electricity can cause injury or death, either directly or indirectly.

Direct contact with a conductive material such as an electrical wire can cause severe injury or death. On the other hand, indirect contact, such as arching, can also cause severe injuries and even death.

Arching occurs when electricity jumps from one connection due to an overloaded circuit. Arching can lead to heart attack, nerve damage, hearing loss, burns, blindness, and death.

What Can You Do to Prevent Electrical Accidents on the job site?

The number of fatal electrical incidents in Australia has continued to decline, from an average of 1.87 deaths per million people in 2000 to 0.43 deaths per million people in 2018-19. However, this data does not mean that contractors should become complacent in the face of electrical risks while they are on the job.

Here are some recommendations from the electricians at Toowoomba Electrical, for safeguarding your work sites against electrical hazards:

#1 Replace broken equipment and tools

Electrocution can occur if you use faulty electrical tools and equipment. Ensure that cables, wires, and cords are free of cracks, cuts, and scrapes.

Defective equipment should be marked “unsafe” or “defective” and taken out of service so that it can be fixed or replaced. If you are not qualified to repair equipment, refrain from attempting to do so in order to avoid injury.

#2 Use cordless tools

It is possible to reduce the risk of electrical shocks by removing potentially hazardous equipment from the worksite. For example, instead of using conventionally powered tools like drills or grinders, employ their battery-powered counterparts that are less likely to cause electrocution. In addition, replace old equipment prone to breaking down and accidents.

#3 Wear PPE

Rigorously adhere to safety regulations, such as using personal protective equipment, at all times. Hard helmets, insulated gloves, aprons, protective eyewear, are examples of personal protective equipment.

#4 Beware of overhead power lines

Workers can be severely burned or electrocuted if they touch high-voltage overhead power and electrified lines. Overhead conductors are responsible for 91 percent of Australia’s electricity supply network deaths. Stay away from power lines and other surrounding equipment at all times.

#5 Use heavy duty extension cords

Incorrectly sized electrical cables can cause overheating and fires. To handle a high electrical load, you need the correct cable size. Outlet adaptors should not be used to the point of overloading a socket. Use the proper extension cord for heavy-duty applications. Conduct regular fire risk evaluations to identify vulnerable areas.

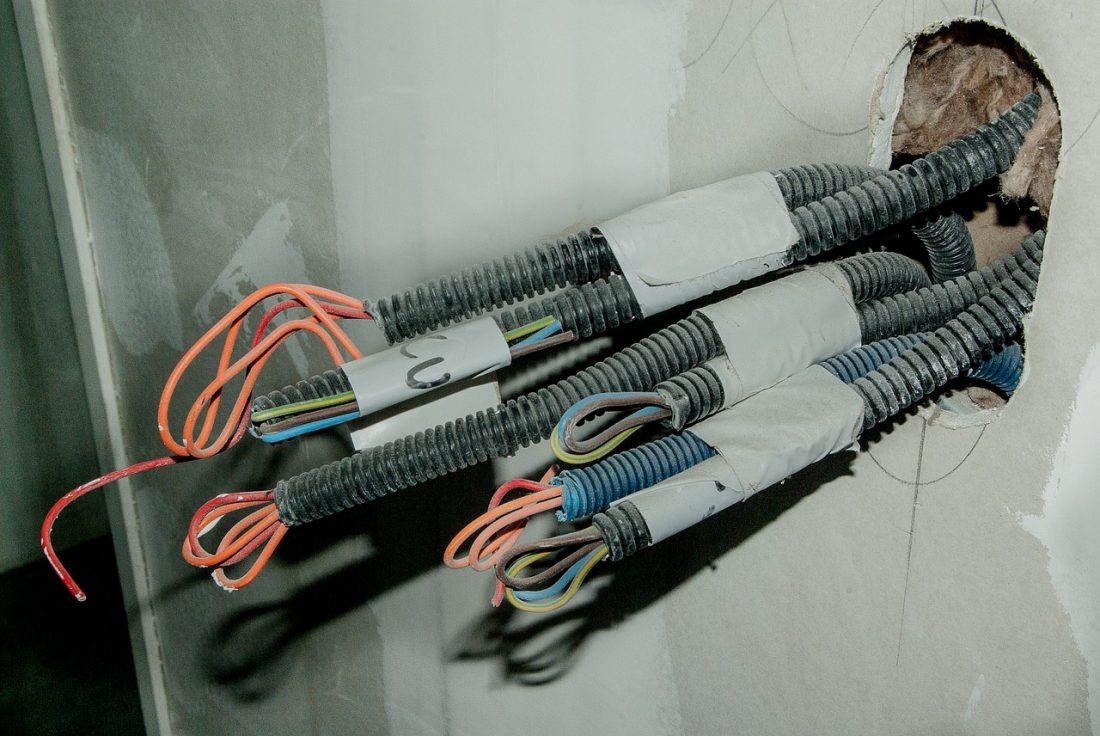

#6 Adequately protect electrical components

The exposure of any electrical components increases the danger of electric shock and burns. These hazards include exposed electricity distribution units, temporary lighting, and broken electrical wire insulators.

Ensure that these components are protected and that any exposed parts are fixed as soon as possible. Even if you think there is no electricity, do not touch the exposed wires.

#7 Check grounding

One common problem on building sites is insufficient grounding. Ensure proper grounding to prevent electrocution. A grounding wire safely discharges electrical energy.

Never remove a plug’s metallic ground pin, as it returns the undesired voltage to earth. Before using any equipment, double-check if it is adequately grounded to prevent any accident.

#8 Use engineering interventions

A deadly electric shock can be prevented by engineering control measures such as residual current devices and sufficient grounding. These safety devices minimise the threat of injury or death. Ensure such devices are installed at the workplace.

#9 Have a clearly written set of safety instructions on hand

Create a set of explicit safety instructions and an administrative control system. Ensure that everyone on the job site understands and adheres to the safety regulations.

Administrative controls are used in conjunction with safe work practices, such as establishing exclusion zones and using permits and warning signs to control the risk.

#10 Conduct regular inspections

Visual inspection can quickly detect possible electrical issues. It is essential to inspect electrical equipment regularly for visible damage or other problems that could make it unsafe. Electrical equipment inspection and testing can help determine whether or not your equipment is safe.

Construction managers have a legal and moral obligation to protect the safety of their employees on the job site.

Therefore, one of the responsibilities of construction managers is to ensure that their job site is safe from electrical hazards.